-

Home

-

About Us

-

Products

- Rotary Die Cutting Machine

- Shearing Machines

- Bending Machines

- WG67K CNC Hydraulic Bending Machin...

- WG67K CNC Hydraulic Sheet Metal Pr...

- WG67K CNC Hydraulic Sheet Metal Be...

- CNC Hydraulic Sheet Metal Bending ...

- WG67K CNC Hydraulic Sheet Metal Be...

- Series WC67 Y/K Hydraulic Sheet Me...

- WG67 Y/K Hydraulic Sheet Metal Pre...

- Series WE67K CNC Sheetmetal Pressb...

- Series WE67K CNC Sheetmetal Pressb...

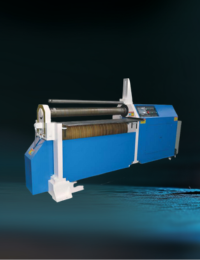

- Rolling Machines

- Other Equipment

-

Application

-

Guide

-

News

-

Contact Us