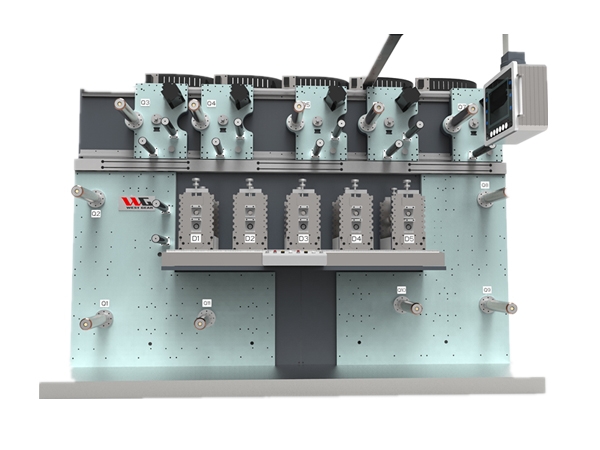

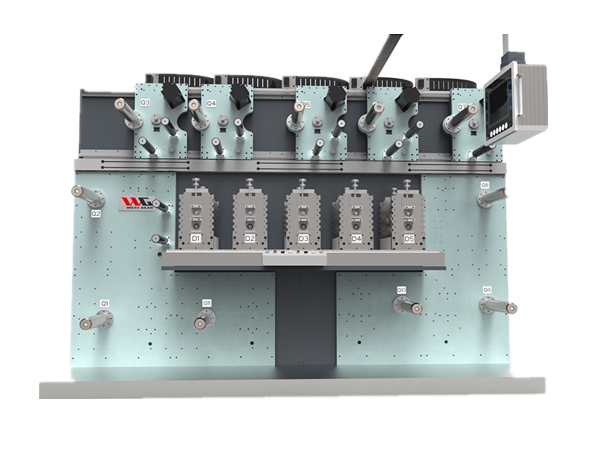

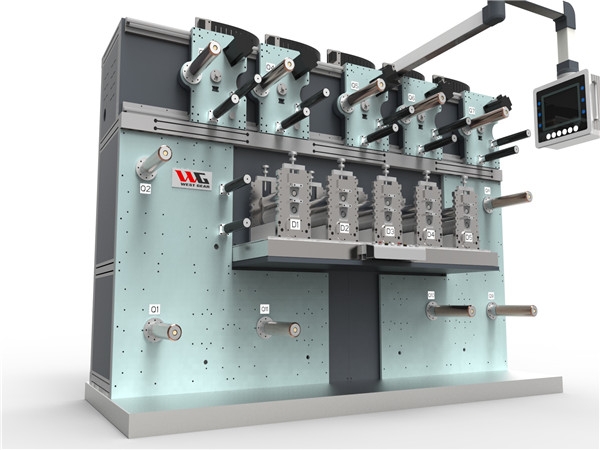

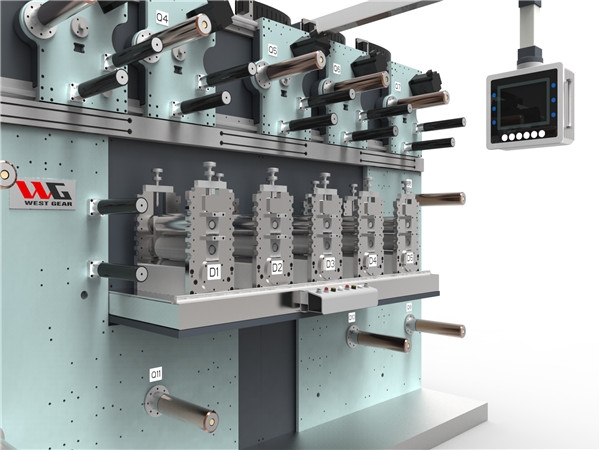

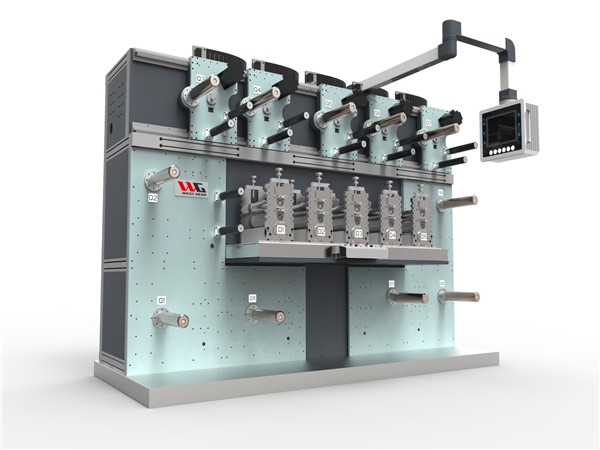

Mechanical advantages:

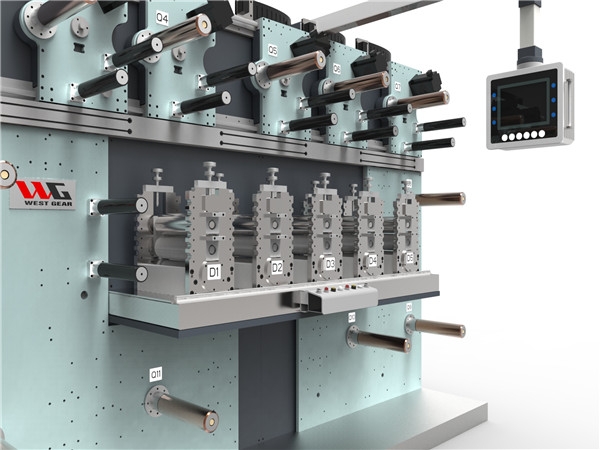

1.Modular design:Flexible combination, standard interface, convenient to add the functions like packaging, receiving, stacking, printing, testing and other additional functions, fast, efficient, stable and precise.

2.Sliding design:Movable stations, shafts and other important components to realize more convenient operation, more reasonable process combination, and guarantee higher yield.

3.Balanced design for components:The core components were developed by us, registered many kinds of national patents(Patent number:ZL 2015 2 0482880.0;ZL 2019 2 0905846.8;ZL 2017 2 0099486.8; ZL 2022 2 0802367.5), keep balance to make the equipment run steadily and guarantee the yield.

Electrical advantage:

1.Precise electronic control technology:Research and develop by ourselves, more advanced electronical control system to realize faster response, higher control precision and stronger stability.

2.Constant tension control system:Research and develop by ourselves, the tension stability is improved remarkably, better tension stability during starting, acceleration, slow down and stopping to improve the yield.

3.More convenient operation:New UI interface design, more rational and simple human-computer interaction; new Chinese and English interface, can customize multiple languages interface according to customers’ demands to facilitate the use of countries around the world.

Technology advantages:

1.Graphite sheet function:One molding solves the problems of graphite sheet partial wrapping and partial back glue problems,reduce labor and production cost. It has achieved multi-layer graphite bonding function,yield reach to 95%, the output, speed and stability is leading in China, share over 90% of graphite industry market.

2.Joint technology of adhesive strip:Solve the problem of high production cost by common asynchronous method, save materials and cost, improve accuracy, speed and stability.

3.Printing technology:It is the leader in die cutting industry, solve the problems of printing after die-cutting, and achieve the goal for printing before die cutting.

4.Fixed length cutting function:Set the cutting length in advance based on the products condition, automatically calculate the feed length of materials. Automatic cutting can be realized without additional guillotine with faster speed and higher precision which greatly improve production efficiency