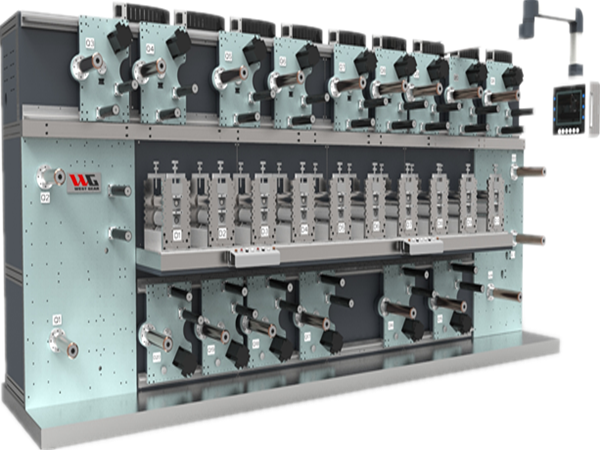

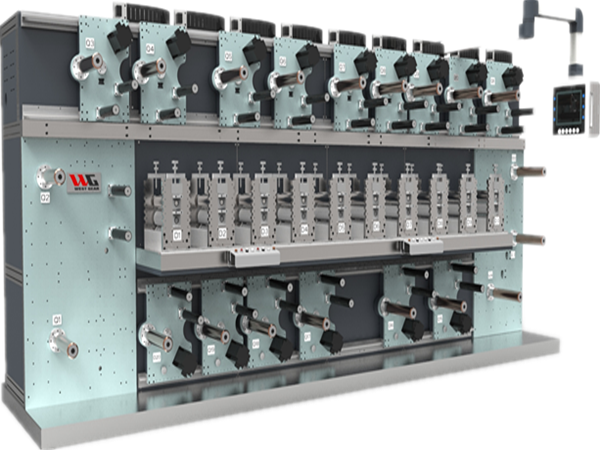

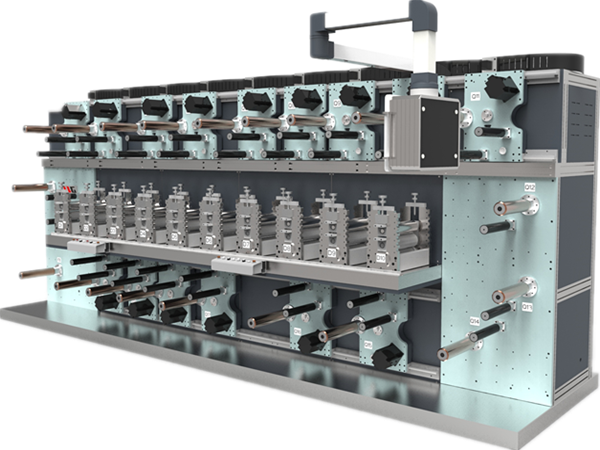

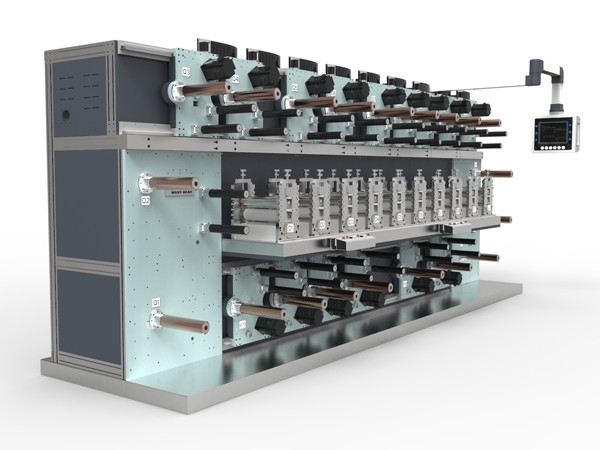

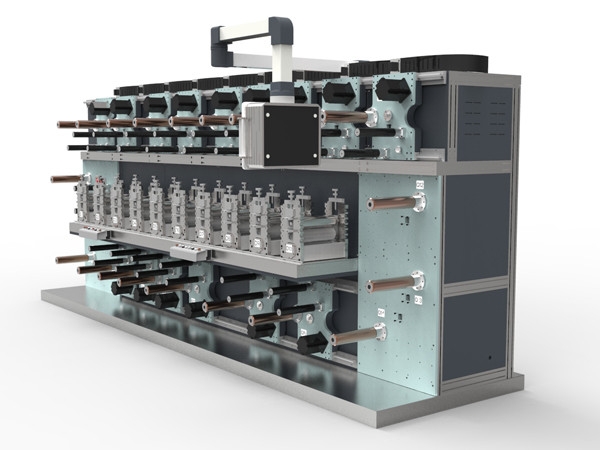

1. The dual systems run two jobs at same time,and enable any combination of stations such as unwinds and rewinds. Satisfy the requirements of complex products. The processes run independently. The cutter shaft can be arbitrarily combined to improve the utilization ratio of the equipment.

2. Island placement modules are available, minimize material waste.

3. Advanced motion control system allows easier operations than before.

4. Max speed 60m/min.

5. Effective die cutting width 270mm

6. The independent servo system of the cutter seat keeps the functions of independent start and stop, positive and negative rotation, synchronous asynchronous operation, island placement fine adjustment for saving cost.

7. Checking function- equipped with automatic deviation correction and convenient operation

8. Independent cutter setting device makes the location of cutter shaft easy.

9. Output alarm, record by piece or meter minimizes wasting.

10. Make operation easy, the constant tension or constant torque mode can be set for the feed shaft.

11. Fault alarm and automatic stop for refueling when running out of material. This function can reduce labor intensity, waste and save materials.

12. Each shaft can be operated independently. The start and stop, positive and negative rotation can be easily handled with one key operation.

13. Multi-block-cutting can be realized by the asynchronous operation.

14. Optional automatic alignment function with setting parameter (max 0.01mm)

15. Fixed length cutting function can realize the cutting at set point, evenly spaced arrangement of productions, breakpoints reduction, and material utilization improvement.

16. An optional anti-electrostatic function can reduce the static electricity and dust, which improve product quality.

17. Optional security function can achieve automatic shutdown to protect the personnel safety.

18. Innovative die-cut systems utilize continuous rolls of material for high-speed converting and greater productivity.

19. HMI 10” Touch Screen Panel with 2 separated rail mounted consoles for easy operator access.

20. Store all process parameters for easy download, upload, easy recall for repeat production and transferring.