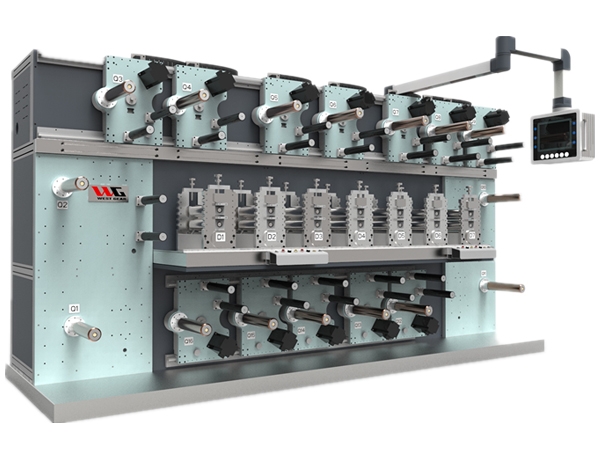

Features:

1.Advanced motion control system allows easier operations than before.

2.Max speed 60m/min.

2.Max speed 60m/min.

3.Effective die cutting width 270mm

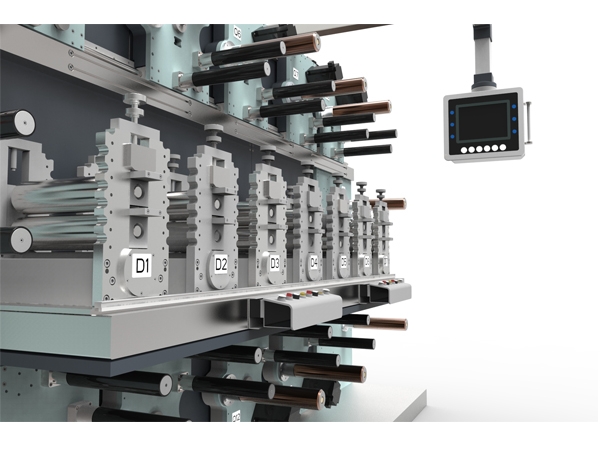

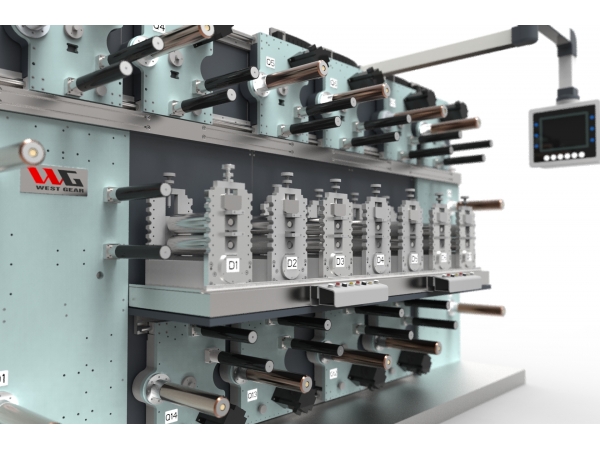

4.The independent servo system of the cutter seat. It can realize the functions of independent start and stop, positive and negative rotation, synchronous and asynchronous operation, fine adjustment and so on.

4.The independent servo system of the cutter seat. It can realize the functions of independent start and stop, positive and negative rotation, synchronous and asynchronous operation, fine adjustment and so on.

5.Feed shaft independent servo system that can feed and regain material easily, realize the positive and negative rotation and start automatically.

6.Automatic deviation correction, convenient operation.

6.Automatic deviation correction, convenient operation.

7.Independent cutter setting device that can make the location of cutter shaft easy.

8.Output alarm, record by piece or meter, materials saving.

8.Output alarm, record by piece or meter, materials saving.

9.To make operation easy, the constant tension or constant torque mode can be set for the feed shaft.

10.Fault alarm and automatic stop for refueling when running out of material. This function can reduce labor intensity, waste and save materials.

10.Fault alarm and automatic stop for refueling when running out of material. This function can reduce labor intensity, waste and save materials.

11.Each shaft can be operated independently. The start and stop, positive and negative rotation can be easily handled with one key operation.

12.Multi-block-cutting can be realized by the asynchronous operation.

13.An optional automatic alignment function with setting parameter (max 0.01mm)

14.Fixed length cutting function can realize the cutting at set point, evenly spaced arrangement of productions, breakpoints reduction, and material utilization improvement.

15.Optional anti-electrostatic function can reduce the static electricity and dust, which improve product quality.

16.Optional security function can achieve automatic shutdown to protect the personnel safety.